When you’re in the market for a new graphite electrode, the process can be as thrilling as it is daunting. It’s like embarking on a treasure hunt, but instead of ‘X’ marking the spot, you’re searching for the perfect fit for your needs. The journey is filled with choices, and each one can significantly impact your operations. So, let’s dive into the adventure of selecting the right graphite electrode, shall we?

First things first, you’ve got to know what you’re looking for. Graphite electrodes come in various forms, each with its own set of characteristics and applications. There’s the standard graphite electrode, which is a workhorse in the industry, and then there’s the high-performance graphite electrode, which is like the superhero of the bunch. You’ve also got the ultra-high-performance variety, which is the crème de la crème, designed for the most demanding applications.

Now, let’s talk about the raw materials. The quality of graphite electrode depends heavily on the purity of the graphite used. It’s like baking a cake; if you start with poor-quality ingredients, you’re not going to end up with a masterpiece. Look for electrodes made from high-purity graphite, as this will ensure better conductivity, higher density, and ultimately, a longer service life.

Next up, we’ve got the manufacturing process. This is where the magic happens, and it’s also where quality can vary greatly. Some manufacturers use a more traditional approach, while others have embraced modern techniques. The method used can affect the electrode’s strength, resistance to oxidation, and overall performance. So, do your homework and find out how your potential电极 is made.

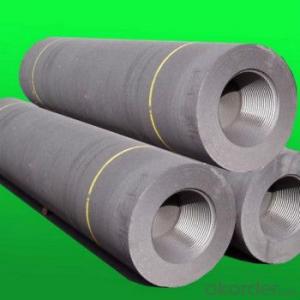

Size matters, too. Not just in the way you might think, but in the context of the electrode’s dimensions. The size and shape of the electrode will affect its performance in your furnace. You’ll want to consider the diameter, length, and even the taper of the electrode. A well-designed electrode will fit snugly in your furnace and provide optimal performance.

And let’s not forget about the current density. This is a critical factor when it comes to the electrode’s ability to conduct electricity efficiently. Higher current density means more power, but it also means the electrode has to work harder. So, you’ll need to balance the need for efficiency with the potential for wear and tear.

Now, let’s chat about the real-world performance. You can have all the specifications and certifications in the world, but if an electrode doesn’t perform well in actual use, it’s not worth the investment. Look for testimonials, case studies, and any other evidence of an electrode’s performance in similar applications to yours.

Warranty and after-sales service are also essential. A good warranty can give you peace of mind and protect your investment, while after-sales service can be a lifesaver when you encounter issues or need advice on how to get the most out of your electrode.

Finally, let’s talk about the cost. While it’s tempting to go for the cheapest option, remember that the cheapest isn’t always the best. Consider the total cost of ownership, including the initial price, maintenance, and potential downtime. Sometimes, investing a bit more upfront can save you a lot in the long run.

In conclusion, selecting the right graphite electrode is a process that requires careful consideration of various factors. It’s not just about finding the one that looks good on paper; it’s about finding the one that will work best for your specific needs and circumstances. Take your time, do your research, and don’t be afraid to ask questions. After all, this is an investment that could make or break your operations. So, happy hunting, and may you find the treasure you’re seeking!