Composite honeycomb sandwich panels are a type of advanced engineering material that has gained significant attention in various industries due to their unique combination of properties. These panels consist of two thin, stiff, and strong face sheets bonded to a lightweight core, which is typically made of a honeycomb structure. The honeycomb structure provides excellent bending resistance and shear stiffness, while the face sheets offer high strength and impact resistance. This article aims to provide a brief overview of composite honeycomb sandwich panels, discussing their properties, manufacturing processes, applications, and future developments.

The Appeal of Composite Honeycomb Sandwich Panels

One of the main reasons composite honeycomb sandwich panels are so popular is their lightweight nature. They are ideal for applications where weight reduction is crucial, such as in aerospace, automotive, and marine industries. The honeycomb core’s unique geometry contributes to the panel’s overall strength-to-weight ratio, making it an attractive option for engineers and designers.

Properties That Make Them Stand Out

The properties of composite honeycomb sandwich panels are what set them apart from traditional materials. They offer high strength, stiffness, and impact resistance, while maintaining a low weight. Additionally, these panels exhibit excellent thermal insulation, sound absorption, and resistance to fatigue and corrosion. These characteristics make them suitable for a wide range of applications, from structural components to decorative elements.

Manufacturing Processes: A Glimpse Behind the Scenes

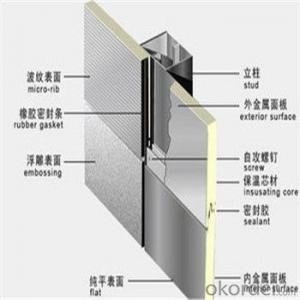

The manufacturing process of composite honeycomb sandwich panels involves several steps, including the production of the honeycomb core, the fabrication of the face sheets, and the bonding process. The core is usually made from materials such as paper, aluminum, or composite materials, depending on the desired properties. The face sheets are typically made from composite materials like carbon fiber or fiberglass, which are then bonded to the core using adhesives or other bonding techniques.

Applications: Where You’ll Find Them

Composite honeycomb sandwich panels are used in a variety of applications across different industries. In aerospace, they are used for aircraft wings, fuselage panels, and interior components due to their lightweight and high strength. In the automotive industry, they are used for body panels, spoilers, and structural components to improve fuel efficiency and performance. Marine applications include hulls and deck structures, where their resistance to corrosion is particularly beneficial.

Innovations and Future Developments

As technology advances, so do the capabilities and applications of composite honeycomb sandwich panels. Researchers are constantly exploring new materials, manufacturing techniques, and applications to enhance their performance and expand their use. For instance, the integration of nanotechnology in the manufacturing process is one area of interest, which could lead to panels with improved mechanical properties and multifunctional capabilities.

The Human Touch: Stories of Success and Challenges

While the technical aspects of composite honeycomb sandwich panels are fascinating, it’s also important to consider the human element. Engineers and designers who work with these materials often have stories of success and challenges, showcasing the ingenuity and perseverance required to innovate and adapt to new technologies. Their experiences provide valuable insights into the real-world applications and potential of these panels.

A Word of Caution: Limitations and Considerations

Despite their many advantages, composite honeycomb sandwich panels do have limitations. For instance, they can be more expensive to produce than traditional materials, and their manufacturing process can be more complex. Additionally, the panels may be susceptible to damage from impacts or environmental factors, which can affect their performance. It’s essential for engineers and designers to carefully consider these factors when choosing to use these panels in a project.

The Road Ahead: Embracing the Future

As we look to the future, the potential for composite honeycomb sandwich panels is vast. With ongoing research and development, we can expect to see even more innovative applications and improvements in their performance. The key to success will be embracing new technologies and materials, while also considering the environmental and economic impacts of their production and use.

In conclusion, composite honeycomb sandwich panels are a remarkable material with a wide range of applications and properties that make them an attractive choice for various industries. Their lightweight, high strength, and versatility are just a few of the reasons why they are becoming increasingly popular. As we continue to explore new ways to improve and utilize these panels, the future looks bright for composite honeycomb sandwich panels.