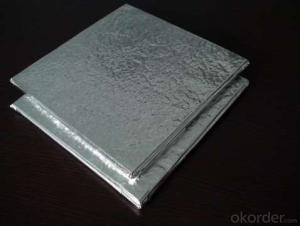

Insulation XPS Board: An Overview of Extruded Polystyrene Applications

Have you ever wondered about the secret behind the warmth of your cozy home during winter, or the coolness in the summer? It’s not just about the heating and cooling systems; it’s also about the insulation that plays a crucial role in maintaining the temperature. One such insulation material that has gained popularity over the years is the Extruded Polystyrene (XPS) board. In this article, we will explore the world of XPS boards, their applications, and why they are a favorite choice for many.

The Science Behind XPS Boards

Before we dive into the applications, let’s understand what XPS boards are made of. Extruded polystyrene is a closed-cell foam made from polystyrene, a thermoplastic polymer. The process of extrusion involves heating the polystyrene and then forcing it through a die to create a continuous board with a rigid structure. This process gives XPS boards their unique properties, such as high thermal resistance and low water absorption.

Versatility in Construction

XPS boards are not just a one-trick pony; they are versatile and can be used in various construction applications. From roof insulation to foundation insulation, these boards provide a consistent and effective thermal barrier. They are also used in the insulation of walls and floors, ensuring that your home stays comfortable all year round.

Energy Efficiency

One of the main reasons why XPS boards are favored is their energy efficiency. With their high R-value (a measure of thermal resistance), they significantly reduce heat transfer, which means your heating and cooling systems don’t have to work as hard. This not only saves energy but also translates to lower utility bills for you.

Moisture Resistance and Durability

Unlike some other insulation materials, XPS boards are moisture resistant. They do not absorb water easily, which makes them ideal for use in areas where moisture is a concern, such as in basements or near water sources. Their durability is another plus, as they can withstand harsh weather conditions and maintain their insulating properties for a long time.

Environmental Impact

While the benefits of XPS boards are many, it’s also essential to consider their environmental impact. Polystyrene is a petroleum-based product, and its production and disposal can have an effect on the environment. However, efforts are being made to recycle and repurpose used XPS boards, reducing their overall environmental footprint.

Installation and Maintenance

Installing XPS boards is relatively straightforward and can be done by professionals or DIY enthusiasts. They are lightweight, making them easy to handle and install. Maintenance is also minimal, as they do not require any special treatment to maintain their performance.

Applications Beyond Home Insulation

While the primary use of XPS boards is in home insulation, they have other applications as well. They are used in cold storage facilities, where their ability to maintain low temperatures is invaluable. In the agricultural sector, they are used for maintaining the right temperature for crops, ensuring optimal growth conditions.

The Future of XPS Boards

As we look to the future, the demand for energy-efficient and environmentally friendly materials is only going to increase. XPS boards, with their unique combination of properties, are well-positioned to meet these demands. Innovations in production techniques and recycling methods will further enhance their sustainability and performance.

Conclusion

In conclusion, XPS boards are a fantastic insulation option for those looking to improve the energy efficiency and comfort of their homes. Their versatility, durability, and resistance to moisture make them a popular choice in the construction industry. While there are concerns about their environmental impact, ongoing efforts to recycle and improve their sustainability are promising. If you’re considering insulation options for your home, XPS boards are definitely worth considering.