Advanced composites have revolutionized the way we approach material science and engineering. These materials are a class apart, offering exceptional strength, lightweight properties, and versatility that make them indispensable in various industries, from aerospace to automotive, sports equipment, and more. But what makes these composites tick? The answer lies in a substance that is as crucial as it is unassuming: the SMC Sheet, or Sheet Molding Compound.

The Unsung Hero of Composites

In the world of advanced composites, the SMC Sheet plays the role of the unsung hero. It’s the silent partner that gives composites their unique characteristics. But what exactly is SMC Sheet? It’s a pre-preg material that consists of a mixture of resin and short fibers, which are combined and then molded into sheets. These sheets can be layered and molded into various shapes and sizes, allowing for the creation of complex parts with exceptional strength and durability.

A Closer Look at SMC

Let’s delve deeper into the world of SMC. The ‘S’ in SMC stands for Sheet, but the ‘M’ and ‘C’ stand for Molding Compound, which is a blend of various elements. The primary components of SMC are resin, which acts as a binder, and short fibers, which provide strength and rigidity. The fibers are typically made from materials like glass, carbon, or aramid, and they are chopped into short lengths to facilitate the molding process.

The process of creating an SMC Sheet is quite fascinating. It starts with the mixing of the resin and the short fibers, which are then spread out into a thin layer. This layer is then covered with a film to protect it and maintain its integrity during the molding process. Once the sheets are formed, they are ready to be used in the production of composite parts.

Why SMC is a Game Changer

So, why is SMC such a game changer in the world of composites? There are several reasons. First, it’s incredibly versatile. SMC Sheets can be molded into a wide range of shapes and sizes, making them suitable for a variety of applications. Second, they offer excellent mechanical properties, such as high strength and stiffness, which are crucial for performance in demanding environments. Third, they are lightweight, which is a significant advantage in industries like aerospace and automotive, where every gram counts.

The Role of SMC in Different Industries

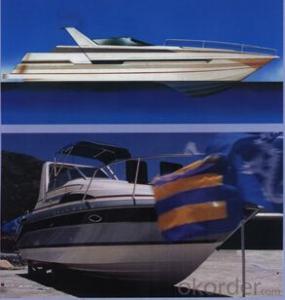

SMC Sheets have found their way into numerous industries due to their unique combination of properties. In the automotive industry, SMC is used for making body panels, hoods, and other structural components. This not only reduces the weight of the vehicle but also enhances its durability and performance. In the aerospace sector, SMC is employed for manufacturing non-structural components, such as interior panels and cargo bins, due to its lightweight and high-strength characteristics.

In the sports equipment industry, SMC is used to create high-performance parts for bicycles, golf clubs, and tennis rackets, among others. The material’s strength and lightweight properties make it ideal for these applications, where performance and durability are key. Even in the construction industry, SMC is gaining popularity for its use in making durable and lightweight building materials.

The Future of SMC

As we look to the future, the role of SMC in advanced composites is only set to grow. With ongoing research and development, we can expect to see improvements in the properties of SMC, such as increased strength, better durability, and even more lightweight options. This will open up new possibilities for its use in various applications and industries.

Moreover, as the world moves towards more sustainable practices, the focus on eco-friendly materials is increasing. SMC, being a recyclable material, aligns well with these sustainability goals, making it an attractive choice for manufacturers and consumers alike.

Wrapping Up

In conclusion, the SMC Sheet is more than just a material; it’s an enabler of innovation and progress. Its unique properties and versatility make it an invaluable asset in the world of advanced composites. Whether it’s in the design of a sleek sports car, the construction of a durable building, or the development of high-performance sports equipment, SMC is the silent force that powers these creations. So, the next time you marvel at the strength and beauty of a composite structure, remember the humble SMC Sheet that makes it all possible.