Smooth geomembrane is versatile and innovative, which has led to its wide use in construction and engineering industries. As a strong supporter of sustainable and efficient building solutions, I believe that smooth geomembrane is indispensable for contemporary infrastructure projects. In this article, I will discuss smooth geomembrane in detail including its uses, advantages and what has contributed to its increased popularity.

The Essence of Smooth Geomembranes

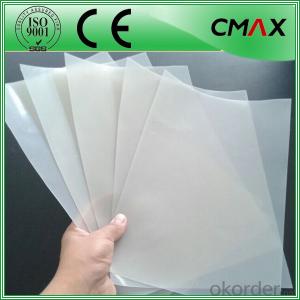

Smooth geomembranes are thin, flexible sheets made from high-density polyethylene (HDPE) or other polymers that can prevent water penetration in many different contexts. They are set apart by their smooth surface finish that combines durability with ease of installation. The smoothness reduces friction making it easier to place the membranes together especially when dealing with large-scale jobs.

Applications of Smooth Geomembranes

Smooth geomembranes have various applications hence they are considered versatile. Some common applications include but not limited to:

Waste Management: Lining landfills with smooth geomembranes prevents the leakage of hazardous materials into the environment.

Water Management: They also act as barriers in reservoirs, canals, ponds among other water bodies thus preventing water loss or contamination.

Agricultural Projects: Farmers construct ponds using smooth geomembranes as well as irrigation systems for crop protection and water conservation purposes.

Construction: For roof membranes and floors where a waterproofing layer is needed to make them durable and long-lasting.

Mining: They are used in mining activities including tailing ponds for waste containment ensuring environmental safety during mining operations.

Benefits of Using Smooth Geomembranes

There are several benefits associated with using smooth geomembranes that explain their extensive application:

Waterproofing: This makes them useful for any situation where there needs to be control over ingress or egress of fluids.

Chemical Resistance: For waste management and mining, this is important because these geomembranes can resist a large number of chemicals.

Puncture Resistance: Therefore, there is minimal risk of punctures or tears that could cause leaks from these materials.

UV Resistance: They are created for outdoor use hence capable of surviving exposure to ultraviolet rays for long periods.

Ease of Installation: Labor costs related to installation are reduced due to the smoothness of these membranes.

The Installation Process

The installation process of smooth geomembranes is both an art and science. It involves several steps including:

Site Preparation: The area should be cleared, leveled, and free from any debris that may compromise the integrity of the geomembrane.

Unrolling: The geomembrane requires careful unrolling without any damage or creases in it.

Securing: To ensure a sealed tight edge, various methods of fastening may be used such as special screws or adhesives.

Joining: In order to create a uniform barrier, seams are either heat welded or joined using adhesives forming continuous barriers without gaps.

Inspection: The final stages involve thorough inspection to ascertain leak-proof quality installations within acceptable standards.

Smooth Geomembranes: An Account of My Personal Experience

After having worked on some projects involving smooth geomembranes, I can confirm that they are effective and easy to use. In one incident in particular, we were required to line a large pond for a local farmer. Besides saving us time during installation, the smooth geomembrane also provided an effective barrier to water loss. The results of this project left the farmer happy and my team with joy.

Are Smooth Geomembranes Here to Stay?

As we look ahead into the future, there is expected growth in demand for smooth geomembranes. Focusing more on sustainability and efficient utilization of resources will make these materials important in many areas. Continuous improvement in material science and engineering will lead to better performance parameters as well as new applications for SMG’s.

In Summary,

Finally these materials have become an integral part of modern building construction and environmental management.This has made them so popular due to their versatility, durability, ease of installation among others.As a person who has seen their benefits personally,I am eager to see how their application will continue expanding towards more sustainable and efficient projects.Smooth geomembranes are beyond just being a material; they represent an evolution in construction methods towards greener and more responsible practices.