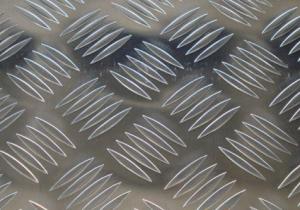

Aluminum extrusion is a versatile and efficient manufacturing process that has been around for over a century. It involves the use of a die to shape heated aluminum alloy into a desired profile. This process is widely used in various industries, including automotive, aerospace, construction, and furniture, among others. In this article, we will explore the world of custom aluminum extrusion profiles and how they can be the perfect fit for your specific needs.

The Beauty of Customization

Custom aluminum extrusion profiles offer a unique advantage over standard profiles. They allow for the creation of parts that are tailored to meet the exact specifications and requirements of a particular project. This level of customization is particularly beneficial for industries that demand precision and accuracy, such as aerospace and automotive. With custom profiles, designers and engineers can push the boundaries of what is possible, creating innovative solutions that were once thought impossible.

The Process of Aluminum Extrusion

The process of aluminum extrusion begins with the selection of the appropriate aluminum alloy. The alloy is then heated to a specific temperature, allowing it to become malleable and easy to shape. The heated aluminum is then forced through a die, which gives it the desired profile. The extruded aluminum is then cooled and cut to the required length. This process can be repeated with different dies to create a wide range of profiles.

Benefits of Custom Aluminum Extrusion Profiles

There are several benefits to using custom aluminum extrusion profiles, including:

1. Enhanced Precision: Custom profiles allow for the creation of parts with exact dimensions, ensuring a perfect fit and reducing the need for additional modifications.

2. Improved Efficiency: By using custom profiles, manufacturers can streamline their production process, reducing the time and resources required to create finished products.

3. Cost-Effectiveness: Although the initial cost of custom profiles may be higher, the long-term savings in terms of production efficiency and reduced waste can make them a more cost-effective option.

4. Aesthetic Appeal: Custom profiles can be designed to meet specific aesthetic requirements, allowing for a more cohesive and visually appealing end product.

5. Versatility: The ability to create a wide range of profiles means that custom aluminum extrusion can be used in various applications, from structural components to decorative elements.

Case Studies: Success Stories

Let’s take a look at some real-world examples of how custom aluminum extrusion profiles have been used to achieve success in various industries.

1. Automotive Industry: In the automotive industry, custom aluminum extrusions are used to create lightweight and strong components, such as door frames, bumpers, and engine mounts. These components not only improve the performance of the vehicle but also contribute to fuel efficiency and reduced emissions.

2. Aerospace Industry: The aerospace industry relies heavily on custom aluminum extrusions for the production of aircraft components. These extrusions are used to create lightweight and durable parts that can withstand the rigors of flight, such as wing components and landing gear.

3. Construction Industry: In construction, custom aluminum extrusions are used for a variety of applications, including window frames, door frames, and structural supports. These extrusions offer strength, durability, and resistance to weathering, making them an ideal choice for long-lasting structures.

4. Furniture Industry: Custom aluminum extrusions are also popular in the furniture industry, where they are used to create sleek and modern designs. From chair frames to shelving units, custom extrusions allow for unique and functional furniture pieces that are both stylish and practical.

The Future of Custom Aluminum Extrusion

As technology continues to advance, the capabilities of custom aluminum extrusion profiles will only continue to grow. With the potential for even greater precision and complexity in design, the future of custom aluminum extrusion looks bright. As industries continue to demand more from their materials, custom aluminum extrusion will be at the forefront of innovation, providing solutions that meet the ever-evolving needs of the market.

In conclusion, custom aluminum extrusion profiles offer a world of possibilities for designers, engineers, and manufacturers alike. With their ability to be tailored to specific needs, they provide a level of flexibility and customization that is unmatched by other manufacturing processes. Whether you are looking to improve the performance of your products, streamline your production process, or create visually stunning designs, custom aluminum extrusion profiles are the perfect fit for your project.